Tata Motors Limited is an automotive company that is part of Tata Groups, and its headquarters is in Mumbai, India. This company manufactures cars, trucks, vans, and buses. The auto manufacturing and vehicle plant of Tata Motors is located in various parts of India, like Jamshedpur, Pantnagar, Lucknow, Sanand, Dharwad, and Pune.

The auto manufacturing and vehicle plant is also in Argentina, South Africa, the United Kingdom, and Thailand. Tata Motors’s Research and Development centers are in Pune, Jamshedpur, Lucknow, Dharwad, India, South Korea, the United Kingdom, and Spain. This blog will explore the interview questions for tata motors careers for Freshers Jobs seekers.

Interview Process

- Written Exam: The first level in Tata Motors’ interview process is a written exam as part of its interview process for certain positions. The written exam typically evaluates candidates’ knowledge, skills, and qualifications relevant to the job they are applying for. The exam may include questions about your technical or functional expertise, depending on the role. They may also assess the candidate’s problem-solving abilities, mathematical skills, and logical reasoning. Expect questions related to numerical reasoning, puzzles, and analytical thinking. The exam might test your English language skills, including grammar, vocabulary, and comprehension. You might be asked to write an essay or respond to a specific prompt to assess your written communication skills.

- Interview Round: The second level in the interview process is the Interview round. In this round, they will ask questions about your educational qualification, interests and skills, strengths and weaknesses, knowledge about the role and the company, career goals, and final-year projects. The interviewer might also ask questions about some situation handling, etc.

- Technical Round: Technical skills are the third level of tata motors recruitment process. If the job opening you are applying for is an IT job, it also includes a Technical round. The exact technical skills might vary depending on the specific job role. Generally, the candidates need to possess specific skills like knowledge of vehicle electrical and control systems, sensors, mechanical designs, computer-aided design (CAD), Software for vehicle designs and engineering, etc.

- HR Round: The candidate selected in the technical round will be contacted by HR.

Apply for new job vacancies through Tata Motors Jobs for freshers.

HR Interview Questions

Given below are the HR interview questions in Tata Motors.

- Tell me about yourself.

The interviewer will first ask you to give a self-introduction. Ensure that you tell about your educational qualifications, skills and interests. Explain how your skills relate to this company’s needs.

- What do you know about Tata Motors?

This question is asked to test whether you have researched the company. This question is an opportunity to showcase that you have done enough research about the company. You can talk about the company’s latest technology advancements and other required information about the company.

- Why should we hire you?

For this question, you can explain how your skills and abilities align with the company’s needs and how it will be helpful for the company’s development.

- What are your strengths and weaknesses?

Explain briefly your strengths and how they will help the company’s profit. In the case of weaknesses, tell them how you are trying to fix your weaknesses.

- Why do you want to work at Tata Motors?

Explain how your skills and abilities are relevant to the company’s needs. Talk about things that you can learn in this company.

- What are your salary expectations?

As a fresher, this question might be challenging for you to answer. It is advisable to say that you are okay with the regular salary.

Apply for the latest job roles by visiting Freshers Jobs in Hyderabad.

Technical Questions

Given below are the technical round interview questions for tata motors recruitment.

- Elaborate on non-functional requirements. Describe the product’s operation, specify product characteristics, and emphasize user-oriented explanations.

- Non-functional requirements are about delineating the operation and attributes of a product with a strong emphasis on the user’s experience.

- They are distinct from functional requirements about performance, usability, security, and more.

- Non-functional requirements include response time, scalability, accessibility, and reliability.

- These stipulations are essential for delivering a favorable user experience and meeting customer demands.

- It’s imperative to have non-functional requirements that are both well-defined and quantifiable to ensure they are achieved during product development and testing.

- Explain the objective of a function requirement and its functions.

- Functional requirements aim to delineate the product’s actions and operations.

- These requirements outline the product or system’s behavior.

- They articulate the product’s attributes, operations, and competencies.

- Functional requirements establish the prerequisites for the product’s inputs, outputs, and processing.

- Instances of functional requirements comprise elements like user authentication, data validation, and report generation.

The interview questions below are Post Graduate Engineer Trainee Interview questions for tata motors careers.

- What is the process for providing the manufacturer with specifications for a pneumatic cylinder?

When instructing a manufacturer on a pneumatic cylinder’s specifications, it’s essential to include the bore size, stroke length, operating pressure, mounting style, and any unique demands.

- Detail the bore size and stroke length requirements.

- Indicate the necessary operating pressure and the preferred mounting style.

- Incorporate specific requirements like cushioning or magnetic sensors, if applicable.

- Take into account the application and environmental conditions when selecting materials and coatings.

- Specify the type of fluid to be utilized in the pneumatic system.

- How should you provide the manufacturer with the specifications for a spring?

Procedure to instruct the specification for the spring to the manufacturer by providing details of materials, dimensions, load requirements, and applications.

- Initiate the process for providing specifications regarding the materials required for the spring, like stainless steel, music wire, etc.

- Instruct about the dimensions for the spring, like the diameter of the wire, outer diameter, and length.

- Provide details regarding the load requirements, the maximum load required for the spring to handle and the deflection needed.

- Instruct about the applications, like the environment where the spring will be used and any other additional or special requirements or factors like cost, corrosion resistance, and fatigue life.

- Contrasting Aerodynamics between Race Cars and Regular Cars.

Race cars incorporate a more significant number of aerodynamic enhancements compared to standard cars to enhance their overall performance.

- Race cars have spoilers, diffusers, and wings to generate downforce and minimize aerodynamic drag.

- On the other hand, regular cars typically feature a sleeker and more streamlined design to optimize fuel efficiency and passenger comfort.

- Race cars also incorporate more oversized air intakes to facilitate improved engine cooling.

- Aerodynamics will enhance the performance of race cars cannot be overstated.

- Examples of exceptionally aerodynamic race cars include Formula 1 vehicles and Le Mans prototypes.

- What is the procedure to reduce pressure in a car?

The first step to reduce pressure in a car is to release some air from the tires.

- Inspect your car’s specific tire pressure through the owner’s manual or the tire itself.

- Measure the current pressure in each tire using a tire pressure gauge.

- If the pressure is too high, release some air from the tire using a tire pressure gauge until it reaches the required level.

- Repeat this procedure for all the tires.

- Check whether the tire pressure is properly maintained for safe and efficient driving.

- What is the importance of wind tunnel testing for car model development?

Wind tunnel testing is essential in the case of car model testing.

- Wind tunnel testing helps in the evaluation of the performance of the aerodynamics of the car model.

- It also helps in identifying the areas that cause drags and turbulence.

- The data derived from the wind tunnel testing process can be used to enhance fuel efficiency and performance.

- This testing process can be helpful in the optimization of the car’s body design and components.

- A few examples of wind tunnel testing are the Mercedes-Benz Technology Center and the NASA Ames Research Center.

The interview questions listed below are Associate Interview questions for tata motors careers.

- Define Swept Volume.

Swept volume refers to the space that a piston clears within an engine cylinder during a single stroke. This figure is calculated by taking the difference between the volume of the combustion chamber at the piston’s lowest point and its volume at the piston’s highest point. It is a critical parameter in the computation of an engine’s displacement. For instance, in the case of a four-cylinder engine with a 500cc swept volume, the total displacement amounts to 2,000cc. Swept volume plays a pivotal role in determining an engine’s power output.

- How does the diesel engine function?

Diesel engines operate through air compression within the cylinder, followed by the precise injection of fuel to initiate combustion.

- The piston compresses air within the cylinder.

- Fuel is introduced into the cylinder at the appropriate moment.

- The heat produced by the compressed air triggers the ignition of the fuel.

- Resulting expanding gasses drive the piston downward, generating power.

- It’s worth noting that diesel engines exhibit higher efficiency when compared to gasoline engines.

- Define a Compression Radio.

The compression ratio represents the relationship between the gas volume within a cylinder when the piston is at its lowest position and the gas volume when the piston is at its highest point. It quantifies the degree to which an engine compresses the air/fuel mixture before initiating combustion. Its increased compression ratios can potentially enhance fuel efficiency and power output. It is used to calculate the compression ratio, and you divide the cylinder’s volume at the bottom dead center by the volume at the top dead center.

The interview questions below are Graduate Engineer Trainee Interview questions for tata motors careers.

- Differentiate between Diesel and Otto Cycle.

| Diesel Cycle | Otto Cycle |

| The diesel Cycle is a constant pressure cycle. | Otto Cycle is a constant volume cycle. |

| It uses compression ignition. | It uses spark ignition. |

| It has a higher compression ratio. | It has a lower compression ratio. |

| It uses diesel engines. | It uses gasoline engines. |

| It has higher thermal efficiency. | It has lower thermal efficiency. |

| It has a longer combustion duration. | It has a lesser combustion duration. |

- What is the procedure to calculate the battery capacity and the motor’s rating?

Battery capacity is computed by considering the energy demands and the discharge rate, while the motor’s rating hinges on the power requirements and efficiency.

- You divide the energy requirements by the discharge rate to ascertain battery capacity.

- In the case of the motor’s rating, you divide the power requirements by the efficiency factor.

- It’s crucial to consider variables like voltage, current, and the duration of operation when performing these capacity and rating calculations.

For example, if you have a battery with an energy requirement of 1000 Wh and a discharge rate of 10 A, the capacity would be determined as 1000 Wh divided by 10 A, resulting in 100 Ah.

- What are emission norms?

Emission norms are rules for limiting the amount of pollutants released by vehicles and industries into the environment.

- Emission norms are rules the government brings up to reduce air pollution.

- They set a specific limit for all the pollutants the vehicles and industries released.

- Carbon monoxide, nitrogen oxides, particulate matter, and sulfur dioxide are a few examples of pollutants.

- As the world knows about the harmful effects of air pollution, emission norms are getting stricter.

- Compliance with emission norms is maintained by conducting routine assessments and imposing penalties for violations.

- List out the effects of exhaust gases.

Exhaust gasses encompass various pollutants that are released from fuel combustion.

- Exhaust gases contain carbon monoxide, nitrogen oxides, sulfur dioxide, particulate matter, and unburned hydrocarbons, which are the significant components to cause air pollution.

- Carbon monoxide is a toxic gas capable of inducing headaches, dizziness, and, in severe cases, fatality.

- Nitrogen oxides are instrumental in smog formation and acid rain.

- Sulfur dioxide is linked to respiratory issues and also contributes to acid rain.

- Particulate matter can lead to lung damage and various health issues.

- Unburned hydrocarbons play a role in creating ground-level ozone, which can trigger respiratory problems.

- The exact composition of exhaust emissions depends on variables like the type of fuel, engine setup, and other factors.

- What produces the white fumes that appear from the silencer when we start an automobile?

Mostly, white fume emissions are typical while starting an automobile. This emission is a part of the combustion cycle that occurs when an automobile is started. As the engine heats up, any condensation present turns into vapor, resembling white smoke. As the engine temperature increases, this vapor dissipates, and the white exhaust smoke, essentially steam, becomes less visible.

- Why do the back wheels of a tractor have a larger radius?

Wheels with a larger radius provide better traction and stability for the tractor.

- Back wheels with a larger radius increase the tractor’s pulling power and enhance the ability to carry heavy loads.

- Since the radius of the wheels is more prominent, it has a larger surface area, which distributes weight evenly. As a result, it reduces soil compaction.

- It helps in overcoming the rough terrains and obstacles.

- It also helps in preventing tripping over.

- For example, Tractors are used in agriculture, construction, and off-road applications.

The interview questions below are Senior Manager Interview questions for tata motors careers.

- List out a few productivity ideas for a Machine shop.

- Enhancing productivity in machine shops can be achieved by implementing lean manufacturing principles, streamlining machine utilization, and investing in automation.

- Adopting lean manufacturing practices, including methodologies like 5S, Kaizen, and Kanban, is crucial in waste reduction and efficiency improvement.

- Optimizing machine usage can be accomplished through well-planned preventive maintenance schedules, decreased setup times, and workflow enhancement, resulting in heightened productivity.

- Investing in automation technologies like CNC machines, robotics, and IoT sensors can increase precision speed and reduce labor costs.

- Equipping employees with training and development opportunities can enhance their skills and knowledge, contributing to heightened productivity.

- Monitoring and assessing productivity through data analytics and performance metrics is vital for pinpointing areas that require improvement and tracking progress over time.

- Define an accumulator in a hydraulics system.

Accumulators are devices used in hydraulic systems to store potential energy and maintain pressure.

- It will store hydraulic fluids under pressure and can be used to power hydraulic machinery.

- It helps in the maintenance of constant pressure in the hydraulic system.

- It also serves as a shock absorber for reducing the effects of sudden pressure changes.

- Some examples of accumulator hydraulic systems are excavators, cranes, and hydraulic presses.

- Define ABC costing and explain the role of an Industrial Engineer in it.

ABC costing, or Activity-Based Costing, is a strategy for allocating expenses to products contingent upon their utilization of resources. In the execution and enhancement of ABC costing systems, industrial engineers hold a pivotal role.

- ABC costing is an acronym for Activity-Based Costing.

- This approach assigns costs to products according to the resources they utilize.

- Industrial engineers are instrumental in the implementation and fine-tuning of ABC costing systems.

- They aid in the identification of activities that steer costs and the determination of cost drivers.

- Additionally, they assist in creating and installing systems for monitoring and apportioning costs grounded on these drivers.

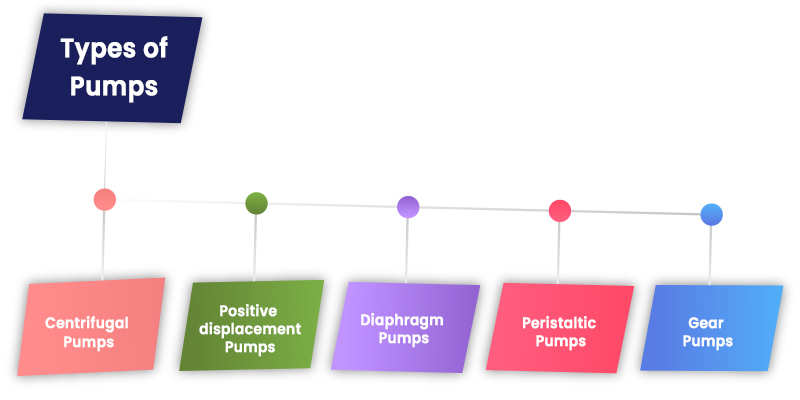

- Name the types of pumps and explain which type of pumps are needed.

Various types of pumps are used in diverse processes, like

- Centrifugal pumps – Water treatment and circulation.

- Positive displacement pumps – Oil and gas processing.

- Diaphragm pumps – Chemical processing.

- Peristaltic pumps – Pharmaceutical and food processing.

- Gear pumps – Lubrication and hydraulic systems

The interview questions below are Floor Manager Interview questions for tata motors careers.

- What is the timing of Override testing in heavy vehicles?

The timing of Override testing of heavy vehicles depends on the manufacturer’s recommendations, like during regular maintenance checks, after modifications or repairs to the vehicle. The test also includes applying brakes at a specified speed to check whether they function correctly.

- What is the purpose of a Back compressor in an engine?

- The purpose of a back compressor in an engine is to compress air used for diverse functions.

- The back compressor is generally used in diesel engines.

- The air that is compressed will be stored in a tank and will be released when required.

- It is also known as Secondary compressor.

- It is significant for the flawless function of the engine and should be maintained regularly.

- What causes the clutch plate to become stiff and develop cracks?

Multiple factors can contribute to the hardness and cracking of a clutch plate.

- Excessive heat can be a root cause of clutch plate hardening and subsequent cracking.

- Inadequate lubrication can increase friction and heat buildup, potentially leading to plate damage.

- Worn or damaged clutch components can place undue stress on the plate.

- Incorrect clutch adjustments have the potential to cause damage to the plate.

- The presence of contaminants within the clutch system may lead to abrasion and wear on the plate.

- Improper driving techniques can also be a factor in causing damage to the plate. For example, riding the clutch.

- What kind of problems will be produced in a vehicle if we remove the cam sensor?

If we remove the cam sensor, it can cause diverse problems in a vehicle, like

- The engineer won’t start properly, or it might stall while driving.

- The power and acceleration of the vehicle may be reduced.

- The check engine light can illuminate spontaneously.

- Fuel efficiency may experience a decline.

- Engine timing could be influenced.

- The vehicle might release increased emissions.

- Transmission shifting may not function correctly.

The interview questions below are ITI Fitter Interview questions for tata motors careers.

- Define PPE.

PPE stands for Personal Protective Equipment. PPE reduces exposure to hazards that cause severe injuries and illness in the workplace. PPE equipment includes safety glasses, shoes, gloves, hard hats, and respirators. It should be selected depending on the hazards present in the specific workplace. The employer’s responsible for providing PPE equipment to their employees and supervising that it is used appropriately. Employees should wear the PPE equipment whenever needed.

- Define PTW.

PTW stands for Permit to work. It is a system of controls used to handle activities of high risk in the workplace.

- What is CNC?

CNC stands for Computer Numerical Control.

- It represents a manufacturing method employing computerized commands to operate machinery.

- This process entails the utilization of software for the precise control of tools and machinery movements.

- CNC machines find applications across diverse automotive, aerospace, and electronics industries.

- Typical CNC machines encompass lathes, mills, routers, and plasma cutters.

- How many categories of gears exist?

Numerous gear varieties are accessible for a wide range of uses, including:

- Spur gears

- Helical gears

- Bevel gears

- Worm gears

- Planetary gears

- Rack and pinion gears

- Internal gears

- Spiral bevel gears

- Straight bevel gears

- Miter gears

The interview questions given below are Trainee Interview questions for tata motors careers.

- How to determine the type of oil to put in the gearbox?

The type of oil to put in the gearbox will be determined based on the model of the vehicle.

- Consult the owner’s manual to find the suggested oil type and viscosity.

- Utilize a top-grade oil that complies with the manufacturer’s requirements.

- Verify the oil level is accurate before operating the vehicle.

- Consistently inspect and replace the oil according to the manufacturer’s guidelines.

- Define MCB.

The abbreviation for MCB is Miniature Circuit Breaker, and it is an electrical switch. If there is an overload or short circuit, the MCb will automatically turn off the electrical circuit. This type of circuit breaker is generally used in residential or commercial buildings. MCBs are available in various current ratings and can be easily replaced if tripped. Examples of MCB brands are Schneider Electric, Legrand, and Siemens.

- What is the count of bearings within the motor?

The quantity of bearings found in a motor is not fixed and depends on the motor’s type and dimensions.

- The number of bearings within a motor can vary, spanning from 2 to 8 or even more.

- In general, larger motors tend to incorporate a more significant number of bearings compared to their smaller counterparts.

- The motor’s specific type also plays a role in determining the count of bearings.

- These bearings within a motor serve the purpose of supporting the rotor and reducing friction among moving components.

For instance, a three-phase induction motor typically features two bearings, while a DC motor may have four or more.

- During the service of the two-wheeler, what observations did you make?

While servicing the two-wheeler, I conducted a comprehensive examination and performed the following tasks:

- Assessed the engine oil level and replenished it if deemed necessary.

- Examined the air filter, either cleaning it or installing a new one.

- Checked the condition of the brake pads and substituted them if they showed signs of wear.

- Inspected the chain and sprocket, applying lubrication where needed.

- Verified the tire pressure and made adjustments as necessary.

- Conducted a thorough examination of the electrical system, replacing any malfunctioning components.

- Tested the functionality of the brakes and suspension.

- Concluded the service by carefully cleaning the bike and giving it a polished, shiny appearance.

The interview questions below are Electrical Engineer Interview questions for tata motors careers.

- What is an electric motor?

An electric motor can transform electrical energy into mechanical energy. It is utilized in various applications like electrical vehicles, industrial machinery and household appliances. There are various types of motors, like DC, AC, stepper, and servo motors. The fundamental principle of a motor is to interact between a magnetic field & an electric current.

E.g. Ceiling fans, washing machines, and electric cars.

- Define Contactor.

A contactor is an electrical switch responsible for switching an electrical circuit on or off. Its primary applications involve the regulation of electric motors, lighting systems, heating devices, and various other electrical loads. Structurally, it comprises a coil, contacts, and an enclosing structure. The coil’s operation involves the generation of a magnetic field, which attracts the contacts to establish circuit closure. Examples of its usage encompass HVAC systems, elevators, and industrial machinery. Contactors are rated according to their capacity to manage current and their ability to switch voltage. They are widely deployed in both industrial and commercial scenarios.

- List out the various kinds of electric motors.

Electric motors change electrical energy into mechanical energy, and there are various electric motors.

- DC motors, which are used in appliances, toys, and automobiles

- AC motors, which are used in industrial machinery and household appliances

- Stepper motors, which are used in robotics and automation

- Servo motors, which are used in precision control applications

- Brushless DC motors, which are used in drones and electric vehicles

- Define the Current transformer.

A current transformer is an apparatus designed for gauging the current within a circuit, achieving this by generating a secondary winding current in direct proportion to the current in its primary winding.

- Comprising both a primary winding and a secondary winding,

- The main winding is linked in series with the circuit responsible for carrying the current to be assessed,

- While the secondary winding is interlinked with a measuring device or protective relay,

- Resulting in the creation of a secondary winding current that aligns proportionally with the primary winding current,

- These devices are commonly deployed for measuring current and safeguarding purposes within high-voltage power systems.

- Define a circuit breaker.

A circuit breaker serves as an electrical switch that is designed to automatically cut off the current flow when it surpasses a specific threshold. Its primary purpose is to safeguard electrical circuits from harm brought about by either overloading or short circuits. Its operation involves the identification of an excessive current and then triggering the switch to disrupt the circuit. Resetting the circuit breaker can be done manually or automatically, depending on the particular type of circuit breaker used. Various examples of circuit breakers encompass thermal circuit breakers, magnetic circuit breakers, and hydraulic-magnetic circuit breakers.

In conclusion, preparing for a Tata Motors interview needs a strategic approach and a deep understanding of the company’s values, culture, and the specific job role you’re applying for.

Remember that you can increase your chances of excelling in the interview with the proper preparation and dedication. In this blog, we delved into Interview questions for tata motors careers.